Realización del Transporte de Productos Médicos Reusables (PMR)

- Después del procesamiento en el lugar del uso. El PMR es transportado al Departamento de esterilización o al área de reprocesamiento para su desinfección. Los PMR contaminados se colocan en un contenedor sellado. Se toma la precaución para no dañar el PMR.

- Post esterilización o desinfección. Después de la esterilización terminal, los PMR esterilizados, protegidos por el embalaje, son trasladados al área de almacenamiento, o si corresponde el uso inmediato, al lugar de su uso. Post esterilización no-terminal o desinfección, los PMR son transferidos al lugar de uso o su almacenamiento temporal. La transferencia se realiza con cierto margen de tiempo y bajo condiciones que limitan los riesgos de recontaminación.

![]() En países con regulaciones para priones. Los PMR con riesgo se separan de los demás instrumentos, y claramente identificados, son transferidos conforme a las regulaciones locales.

En países con regulaciones para priones. Los PMR con riesgo se separan de los demás instrumentos, y claramente identificados, son transferidos conforme a las regulaciones locales.

Los contenedores de transporte : de PMR contaminados se diferencian visiblemente de los contenedores para productos esterilizados o desinfectados. Sea cual sea el tipo de transporte, los productos contaminados no utilizan la misma vía de transporte que los esterilizados o desinfectados.

- Transporte interno, a mano, o en carro o contenedor de transporte : los contenedores de dispositivos contaminados siguen rutas designadas para evitar áreas de alto tránsito y las de atención al paciente. Los carros de transporte y mesas son lo suficientemente grandes como para que todos los paquetes se apoyen en sobre la superficie, no deben sin sobresalir de los bordes. Los artículos contaminados nunca se colocan juntos con los esterilizados o descontaminados en los carros de transporte. Si los carros se utilizan alternativamente para transportar artículos contaminados y descontaminados, deben limpiarse entre cada uso, conforme a las instrucciones del fabricante de los carros (IUF). Los carros de transporte están son diseñados y fabricados de materiales que permiten la fácil limpieza, preferentemente automática. Si los carros salen de un área con aire controlado deben ser cerrados y supervisados. La cubiertas reusables para tapar los carros de transporte u otros medios de transporte deben limpiarse después de cada uso y deben tener aberturas autosellables.

- Sistemas internos de distribución automatizados y neumáticos : Por diseño difieren las rutas contaminadas de las de material esterilizado. Su operación es supervisada por personal autorizado y el equipamiento se limpia y desinfecta según las instrucciones del fabricante (IUF).

- Transporte interno a través de ascensores o montacargas : Estos deben ser destinados a productos médicos reusables (PMR) contaminados, o para PMR esterilizados y desinfectados. Los montacargas deben ser lo suficientemente grandes para permitir la colocación segura de los contenedores. Los montacargas son diseñados para su fácil limpieza y se limpian en base a la rutina según las políticas de la Organización. Los montacargas limpios deben estar ubicados en áreas designadas como “limpias.” Los paquetes esterilizados estarán contenidos en un recipiente cerrado, en una caja cerrada o en una bolsa plástica.

- Transporte externo : Los vehículos serán destinados preferentemente al traslado de PMR. Si el vehículo es usado para el transporte de ambos tipos de dispositivos, los contaminados y descontaminados, deben ser colocados en áreas con separación segura dentro del vehículo. El diseño y material utilizado en la construcción de todos los medios de transporte (motorizados o manuales) deben permitir la limpieza y desinfección adecuada. El compartimiento de almacenamiento es completamente cerrado. Los vehículos son de fácil carga y descarga. Los contenedores se fijan dentro para evitar daños y contaminación por derrames. Los vehículos cargados y listos para el transporte no se dejan desatendidos en áreas desprotegidas.

Todos los PMR se transportan con cuidado. Los contenedores utilizados para el traslado de material contaminado, a mano, deben ser trasladados en planos paralelos al piso para evitar derrames o que el PMR se mueva.

Los operadores de transporte reciben la capacitación apropiada referente a los riesgos relacionados con el manejo de las cargas.

Los operadores de transporte, encargados de la carga de elementos contaminados reciben la capacitación apropiada sobre el riesgo relacionado con el contenido contaminado de los contenedores.

En los vehículos de transporte Personal debe disponerse de equipos de protección personal (EPP) y kit de para derrames de biorriesgo.

![]() Corresponde aplicar regulaciones locales para el transporte externo de material peligroso y sustancias infecciosas.

Corresponde aplicar regulaciones locales para el transporte externo de material peligroso y sustancias infecciosas.

Después de la desinfección o esterilización « no terminal », los PMR no están protegidos frente a la contaminación ambiental o manual. La transferencia debe realizarse en condiciones controladas. El nivel de cuidados estará ligado al uso previsto del PMR conforme a los principios de la clasificación de Spaulding.

Después de la esterilización terminal, los PMR están protegidos por su envoltura. Se debe tener precaución para evitar rupturas o daños del envoltorio. Los daños son informados sistemáticamente.

Se preparan procedimientos operativos estándar (POES) conforme a los principios del manejo de calidad.

Se aplica análisis de riesgo. El embalaje se adapta a las condiciones de transporte. El análisis de riesgo también evalúa las alternativas del transporte, tales como humedad excesiva, condensación a causa de la exposición a temperaturas extremas, polvo y suciedad, excesiva presión y microorganismos.

La validación del proceso de transporte asegura :

- Debe realizarse entrenamiento y los certificados de entrenamiento deben estar disponibles, tanto para el personal interno como externo (cuando el transporte es subcontratado).

- Se deben cumplir las medidas seguridad laboral y salud ocupacional, en particular para el transporte de PMR contaminados.

- Los POES están vigentes e incluyen resultados del análisis de riesgo.

Recomendaciones de WFHSS para el transporte

- Seguir rutas diferentes para los elementos contaminados y esterilizados o desinfectados.

- Dar al personal de transporte (empleado por la Institución de salud o externo) la adecuada capacitación de seguridad laboral y salud ocupacional, referida a contaminación y riesgos del manejo de carga.

- Implementar el transporte de acuerdo a los principios de calidad y someterlo a un proceso de validado. Realizar análisis de riesgo para adaptar los embalajes a las condiciones del transporte.

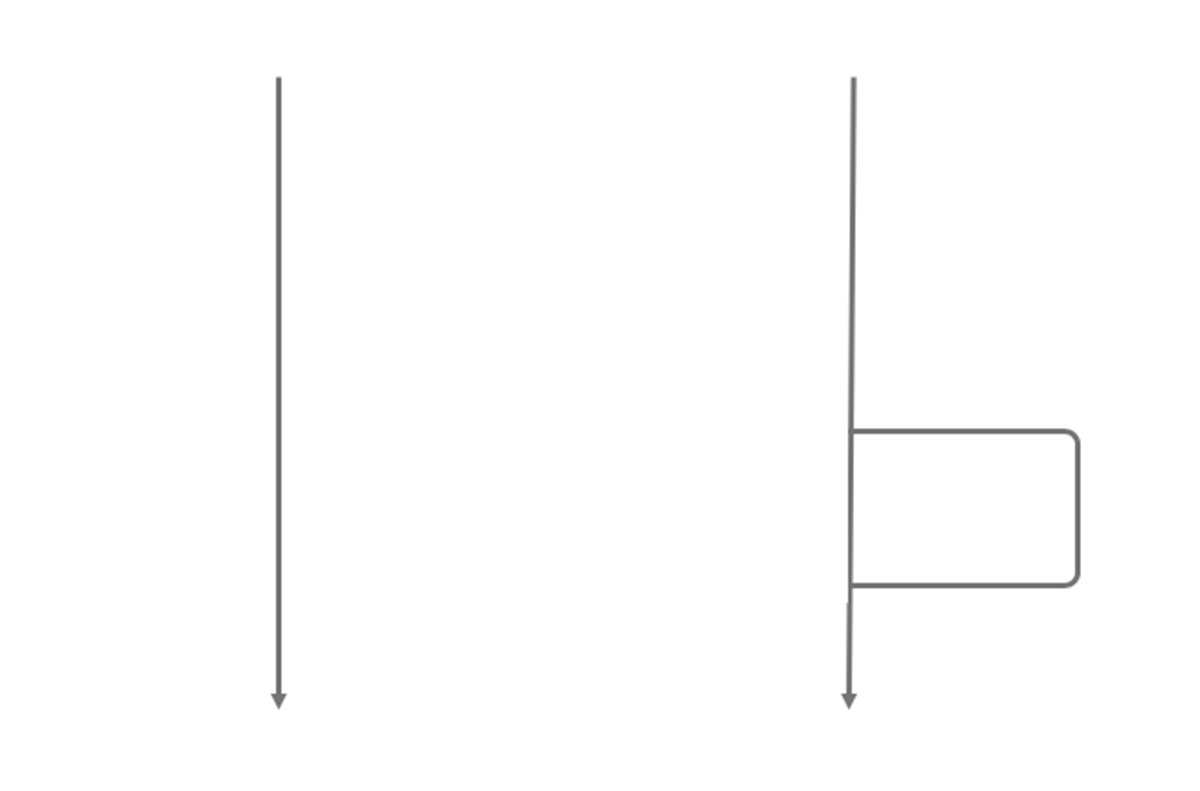

Switch in landscape mode to use the flowchart

RMD after point of use processing

Go to Transport– Key principles →

1 of 12 Transporte del PMR contaminadoBy trained operators personal aware of contamination risks

Go to Transport of RMD after use →

2 of 12 PMR en la unidad de reprocesamientoRMD after point of use processing

Go to Transport – Key principles →

3 of 12 RMD in reprocessing unitPackaged sterile RMD or disinfected RMD

Go to Transport– Key principles →

4 of 12 Transport del PMR esterilizado o desinfectadoBy trained operators personal

Go to transport of RMD after disinfection or sterilization→

5 of 12 AlmacenamientoRMD in sterile packaging

Go to transport key principles →

6 of 12 Reproceso en el lugar de usoCare unit or operating theatre

Go to Transport key principles →

7 of 12According to transport SOP

Go to![]() WFHSS recommendation for transport →

WFHSS recommendation for transport →

Traceability and controls

Go to Transport and quality →

9 of 12According to SOP’s

Go to![]() WFHSS recommendation for transport →

WFHSS recommendation for transport →

According to SOP’s

Go to transport of RMD after disinfection or sterilization →

11 of 12Traceability and controls

Go to Transport and quality →

12 of 12- ISO 17664-1: Processing of health care products — Information to be provided by the medical device manufacturer for the processing of medical devices (2017)